Britain's Lewis Hamilton escaped serious injury after a collision with Max Verstappen at the Italian F1 Grand Prix.

The world champion felt the cockpit protection device saved his life after his title rival's Red Bull landed on him in yesterday's race.

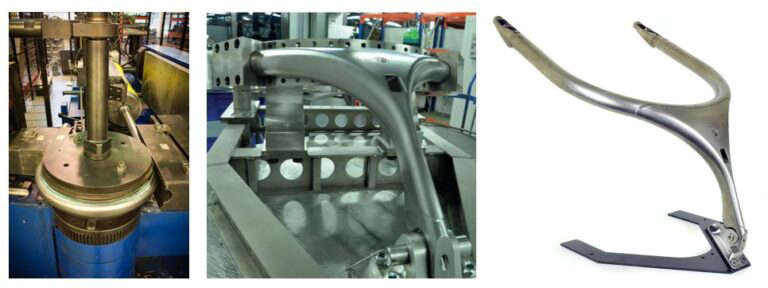

The life-saving Halo system which stopped the rear wheel of max Verstappen's Red Bull Racing car from impacting on Lewis Hamilton's head is made by Oxfordshire-based SST Technology using tube bending technology from Scarborough based engineering firm Unison.

SST Technology became the only British-based precision fabricator authorised to produce the life-saving Halo titanium driver protection system after investing in a Unison Breeze all-electric CNC tube bending machine.

It has also equipped the business to complete numerous complex structural projects involving titanium tube – including roll-cage structures for military vehicles and aerospace components.

The machine, a Unison Breeze 130 mm ‘large diameter’ multi-stack tube bender, was purchased to help SST produce high-performance optimal-flow exhaust systems for Formula 1, IndyCar and other motor sport sectors.

With a pedigree in motorsport components and a powerful new tube bending machine to hand, however, SST’s thoughts quickly turned to driver safety. The exceptionally tight material control, production parameters and dimensional tolerances provided by the all-electric Unison Breeze tube bender, combined with SST’s considerable experience in the development and manufacture of ultra-precise fabrications, led to the company’s Halo design securing FIA conformity for use in Formula 1, Formula 2 and Formula E motorsport and being adopted by several race teams.

SST’s Halo design requires the precise bending of titanium tube of 4 mm wall thickness.

Titanium, however, is notoriously difficult to bend, a characteristic that makes creating tubular structures for aerospace and motorsport applications particularly challenging. Traditionally, ‘hot bending’ – a process involving the use of super-heated tooling – has been used to overcome the challenges of bending titanium. However, the very process of hot bending presents a number of issues. For example, the use of super-heated tooling requires considerable care and can present a hazard to operators; complex modifications must be made to bending machinery, and tooling heat-up times are lengthy. By contrast, Unison’s machines enable the safe, precise cold bending of titanium. With advice and application support from the technical team at Unison Ltd, SST were therefore able to develop a cold-bending process for their Halo design that allowed for the low elongation of the metal and delivered precise results.

Unison Key Account Manager, Steve Haddrell said:

“To successfully cold-bend titanium, factors such as material quality, tooling configuration, machine design and flexibility of control need to be considered, this is because any variation in material quality, any lack of rigidity in the mechanics of the bending machine and any failure to achieve repeatability time after time will invariably lead to failure.

With exceptional power, optimal rigidity, precise mechanical motion and all-electric control for accurate, effortless repeatability, we knew the 130 mm Breeze was the ideal machine for precision-bending SST’s Halo design. With material quality assured, it really came down to working with SST to establish the correct tooling configuration and programming of the Unison Unibend machine operating system.”

SST Technology’s Group Business Development Director, Daniel Chilcott said:

“Investing in the 130 mm Unison Breeze machine has clearly paid dividends, tool changes are rapid, programming is incredibly user friendly, while the automatic setup ensures uncompromising levels of accuracy and repeatability. Sufficiently impressed with the capabilities of our 130 mm machine, we have also purchased a smaller 65 mm Breeze model for the production of more intricate pipework and parts for aerospace and gas turbine applications. Combining this capability with our AS9100REVD accreditation means we are perfectly set up to support leading aerospace propulsion, fluid and air system OEMs.”

Injured Yorkshire Coast Seal Back in the Water

Injured Yorkshire Coast Seal Back in the Water

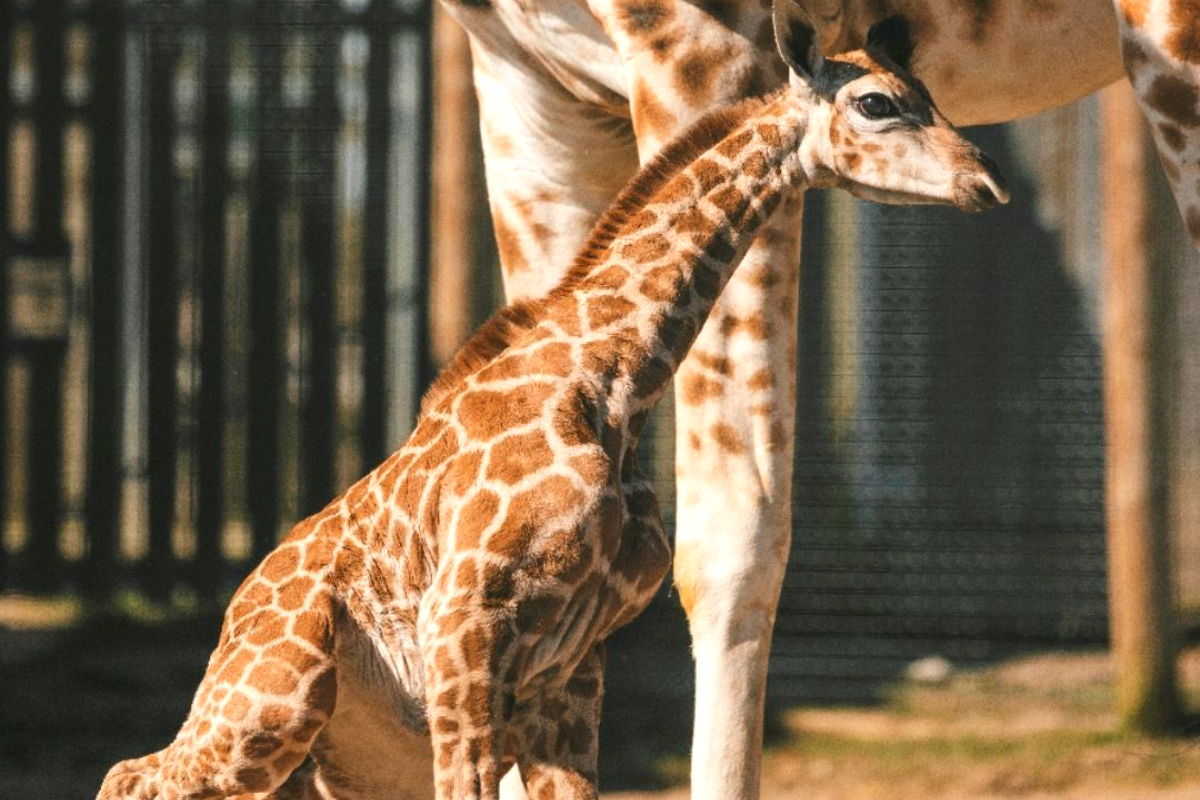

Flamingo Land Welcomes Baby Giraffe

Flamingo Land Welcomes Baby Giraffe

Scarborough and Whitby MP to Launch Petition for Return of Stroke Services

Scarborough and Whitby MP to Launch Petition for Return of Stroke Services

UK Mayors Being Urged to Buy Scarborough Buses

UK Mayors Being Urged to Buy Scarborough Buses

Free Music Events in Scarborough to Raise Funds for Andy's Man Club

Free Music Events in Scarborough to Raise Funds for Andy's Man Club

Scarborough's Cross Lane Hospital Receives Heartfelt Gift

Scarborough's Cross Lane Hospital Receives Heartfelt Gift

Saint Catherine’s Becomes First UK Hospice to Launch Masonic Aware Initiative

Saint Catherine’s Becomes First UK Hospice to Launch Masonic Aware Initiative

Candidates Confirmed for First Scarborough Town Council Elections

Candidates Confirmed for First Scarborough Town Council Elections

Scarborough Station Set for Multi-Million-Pound Roof Renovation

Scarborough Station Set for Multi-Million-Pound Roof Renovation

Renewed Appeal Following "Shocking" Arson in Whitby

Renewed Appeal Following "Shocking" Arson in Whitby

Six Candidates Standing to Become First Elected Mayor of Hull and East Yorkshire

Six Candidates Standing to Become First Elected Mayor of Hull and East Yorkshire

Construction to Start on Whitby Maritime Hub

Construction to Start on Whitby Maritime Hub

Comments

Add a comment